Alan Wade

A great treat

Randy Oliver of Scientific Beekeeping fame advises that employing synthetic miticides to control Varroa is a most unwise endeavouri. Their use is either being abandoned, curtailed or, where they have failed to control mites completely, are being deregistered. Randy has questioned their being promoted for use here in Australia as they are, at best, but a short term solution to an ongoing problem.

A twofold problem

Using miticides is not a single problem. It is a twofold problem. Let me elaborate. Firstly no miticide, synthetic or natural, will kill all mites. As club members, Mark Patterson and Peter Czeti, keep saying:

‘Using chemicals will never solve the mite problem. Only finding bees that can control mites themselves will work’.

Secondly natural miticides are, like the synthetic miticides, not the solution to Varroa. If we take the synthetics off the agenda we are left with natural remedies. Problem is that natural miticides, those that work, are quick action only. With the notable exception of formic acid they only kill phoretic mites, the mites that roam freely in the hive or are attached to adult bees. Natural arachnicides fail to target the two thirds of hive mites attached to developing pupae locked away safely under wax cappings: the synthetics only do so because they are long acting and capture emerging mites.

This said natural miticides are very effective in treating broodless bees and are obviously useful for treating swarms, shook bees and seasonally broodless colonies. Moreover brood interruption is widely practiced as it interrupts mite production and fully exposes mites to treatment.

The alternative, regular repeat treatment, can be effective but is time consuming. In my reading, most beekeepers have neither the time, resources nor inclination to so molly coddle their bees. We are still left with the problem that synthetic arachnicides create their own problems, not only because they persist and contaminate hives and beeswax but because they eventually fail to kill mites and because they promote the development ever more virulent mite-virus associations.

At the other end of the spectrum a sizeable number of North American, European, African and South American beekeepers now operate their colonies entirely free of chemicals. How is this possible?

Honey bees of African descent quickly developed natural tolerance to both Varroa and Tropilaelapsmites, a trait they share with their natural mite hosts, the dwarf and giant Asian honey bees. Simply put these bees require no treatment and have effective means, detecting and removing the parasites and brushing them off, to keep numbers very low. Elsewhere in the world, scattered populations of western honey bees have evolved to develop mite tolerance so the question of treating mites is then again no longer an issue. Moreover prodigious efforts to raise Varroa tolerant stock has had some success. Though decades in the making it, too, is fraught with the problems of inbreeding and outcrossing.

In the normal circumstance, however, not treating mite ridden bees will spell their quick – the bees – demise. Thomas Gray’s 1750 Elegy Written in a Country Churchyard lamenting the unsung demise a worthy farm labourer rings clearii:

The curfew tolls the knell of parting day,

The lowing herd wind slowly o’er the lea,

The plowman homeward plods his weary way,

And leaves the world to darkness and to me.

Smiting the Mite

What is the clearest way forward? Well we can choose either to replicate the natural defences of native dwarf and giant honey bees – allow them to swarm repeatedly or induce artificial brood breaks (e.g. shook swarm), regularly remove sealed drone brood that mites favour – or apply proven natural miticides, simple organic acids and natural oils.

The first of these options – inducing brood breaks – is inherently counterproductive. Inducing broodlessness exposes all mites to treatment but has whiskers on it. Limiting colony expansion by suppressing bee nursery activity results in fewer bees. All being equal, this translates to a smaller honey crop and reduced hive pollinator potential. Nevertheless a short brood free period in late autumn or in winter will have a lesser impact. Whatever strategy we take, we still have to acknowledge the fact that mites take their toll.

Any kind of treatment stems development of natural honey bee mite tolerance. In technical lingo simply killing mites curtails selection of honey bee for ‘Varroa Sensitive Hygiene’ (VSH) perpetuating dependence on treatment.

The Cuban experience shows us that failing to treat actually ‘works’. After a short period of allowing beekeepers to use of oxalic acid to reduce mite numbers, a government edict banned all treatment. This decision devastated beekeepers but the pain was short-lived.

Today Cuba has a thriving apiary industry operating around a quarter of a million beehives treatment free. Cuban bees still have Varroa and associated viruses (including deformed wing virus), but their bees have evolved a natural mite and virus tolerance and are truly productive.

So controlling Varroa without resorting to the use of now failing arachnicides is actually possible. American apiarists lose up to 40% of their colonies annually largely because of extensive and inappropriate treatment using synthetics.

However, since we have neither a command and control economy nor a society that would tolerate control of beekeepers by preventing intervention, we need some other direction. In this we can hope for development of an industry selling Varroa (and potentially Tropilaelaps) tolerant stock while also encouraging beekeepers to employ simple treatments with natural products to suppress mite numbers, but only as needed.

Treatment at a stretch

We have reviewed mite swiping using a plethora of natural oils and their principal constituentsiii: Randy Oliver has tested many of these remedies, those that have seemingly worked well in laboratory trials, and found that most fail dismally in the hive. Instead he advocates extending the action of proven natural miticides that typically degrade within a few days in the hive and only kill roaming mites. Why not instead, he suggests, work on formulations that release the treatment agent slowly and so target mites as they emerge from their sealed waxen shelters.

His counseliv for Varroa control down under is:

to use formic acid, oxalic acid, and thymol (perhaps also the β hop acids) in rotation; and

to include an induced [if needed] annual brood break.

Of course the devil is in the detail. Implicit in his recommendation is to use the acids and thymol in rotation and in formulations that last longer than at most a few days. A linger longer strategy if there ever were one.

Randy Oliver does not use synthetic arachnicides. He and his sons keep mites in check across a vast operation making use of natural products (mainly the simple organic acids) and by employing Varroa tolerant stock requiring only minimal treatment. Randy is betting that his Golden West queen bees, now on sale and whose progeny have a good measure of Varroa tolerance, will be winners.

Let’s examine these treatments more closely to see if we might come up with an effective mite control regime, one that is not too costly, one that obviates the need to use any synthetic miticides, and one that avoids the seemingly insurmountable problems the mites present.

Oxalic acid extended

Oxalic acid is officially registered for use as Api Bioxal®. Oxalic acid has two established modes of application.

The first recommended by Oliver is dribble formulations of oxalic acid: 2.5, 3.2 and 4.2 % (w/v) water-alcohol solutionsv. The standard 3.2 % solution is used to treat swarms and broodless bees and has been used for many years. He finds that his weak solution 2.5 % formulation is suitable for small colonies such as nucs where the standard 3.2 % (officially sanctioned) treatment would be injurious to brood. The 4.2% formulation he employs to treat heavily infested and potentially collapsing bees, i.e. where a radical intervention rescue mission is warranted.

His alternative oxalic acid application is that of a glycerine – oxalic acid mix. The action of the acid is extended from days to some weeks so is effective in killing mites as they emerge together with eclosing parasitised bees. The details of this scheme are outlined in Smite the Mite Part IIvi.

The soon to be registered Aluen CAP® employs 10 g of oxalic acid mixed with 20 g of glycerine impregnated into cellulose strips. Randy notes that this and other published formulationsvii,viii employing a higher titre of glycerine are less effective than his standard 1:1 weight for weight OA-glycerine mix. See again Smite the Mite Part II for details. The advantages of extended oxalic acid application is that it can be applied to functioning colonies when supers are in place.

Formic acid extended

Details of use of formic acid as Formic Pro are similarly outlined in Smite the mite Part II. Formic Pro is a formic acid impregnated polysaccharide gel that slowly releases the acid when the packaging envelope is snipped open. For all intents and purposes this amounts to treatment of stand alone (super free) brood boxes (singles or doubles). Screened bottom boards need to be covered, hive lids should be fit closely and ventilation holes in migratory lids need to be firmly plugged and entrances left fully open. This ensures effective exposure of brood to circulating acid fumes with sufficient ventilation to prevent bee asphyxiation.

Of this product, Oliver makes two pertinent observations. Firstly he questions the supposed adverse direct impact of formic acid in ‘forcing’ queen bee supersedure. He posits the effect is that of the acid fumes acting on nurse bees particularly in hot weather: stressed workers may initiate queen balling and hence emergency queen replacement. His experimentation with removal of queens and caging them in an incubator during the initial flash treatment phase to avoid queen loss resulted in very mixed outcomes. Removing queens to an incubator or nuc sometimes failed – queens were lost – so can hardly be recommended.

In the same 2021 reportix Oliver points to a 2006 formic acid ‘fogging trial’ that had been undertaken by James Amrine and Robert Noelx. In that trial brood and bee mortality were very low and a single treatment sufficed. With this in mind, Oliver tracked the pattern of mite kill using Formic Pro. He dissected brood comb showing that most mite mortality occurred during the first four days of treatment. He found that two strips of Formic Pro applied for a period of fourteen days was more effective in killing mites than the extended twenty day application where single strips are applied in sequence at a ten day interval. This signals the intrinsic action of formic acid, its ability to target all hive mites at the one time obviating the need to open the hive for repeat treatment.

In a further trial, details of which are yet to be publishedxi, Oliver has found that a daily dose of 20 g of ‘slow-release’ 65% formic applied over four consecutive days will kill virtually every mite in a double-deep hive. The treatment employs perforated ziplock bags containing acid absorbed onto meat pads. His schema is presaged by a new postingxii detailing an investigation of the impact of formic acid on worker and queen bees. A similar repeat 4 daily dose of 20 g of 65% formic acid absorbed onto cardboard strips was found to be effective in control of Acarapis, Tropilaelaps and Varroa mitesxiii.

The colligative properties (physical behaviour) of formic acid (m.p. 8.5 0C. b.p 100.8 0C) are remarkably similar to those of water. They evaporate together at a similar rate. My supposition is that fewer or smaller holes to regulate formic acid release will be required as the treatment conditions climb towards the normal upper recommended treatment limit of 30 0C.

Postscript update: Oliver recommends use of cheap Nassenheider evaporators (to deliver 65 % formic acid) to regulate the evaporation rate – in each of several wick types – and simply sit in an empty (ideally shallow super) above the brood box(es). A New Zealand supplier recommends that they be operated in spring and autumn where conditions are mild (<30 0C) and where there are active brood nests (and easily monitorable mites) and no honey supers. Treatment should not be too late in the season, that is after long-lived, so-called diutinous bees, have been produced. The idea here is that treating weakened bees in late autumn is pointless as killing mites will not leave hives in a condition, even if there are a lot of bees, that will survive winter.

In another study using mite drop count as a measure of mite kill, Menzies, Olmstead, McCallum and Cutlerxiv report that efficacies for a range of acid treatments following Ontario guidelines for the use of formic acidxv. Their reported treatment kill rates were 62.0%, 89.4%, and 82.4% for 65% liquid formic acid, 14-day Formic Pro, and 20-day Formic Pro treatments, respectively. This outcome supports Oliver’s thesis that single application Formic Pro is actually better than the extended repeat application. Oliver would now appear to have found a ‘sweet spot’ where quick and repeated formic acid treatment (over four days) has resulted in a much higher mite mortality. Handling formic acid, a fuming and corrosive liquid, will of course be a challenge but we await Oliver findings.

Kochansky et al.xvi describe use of an inert polyacrylamide gel mixed with formic acid that steadily releases the acid over a period of 2-3 weeks.

Thymol extended

Thymol (registered for use as Apiguard®) is an effective miticide when applied to broodless bees – with supers off. It seems likely that menthol and carvacrol (with the same carbon framework) may act similarly, but their effectiveness as miticides has not been well demonstrated. All of course would taint honey so a ‘honey supers off’ treatment is essential.

Oliver has undertaken a thorough review of the use of thymol and its purported adverse effect on broodxvii. A new and extended thymol treatment, slow release of the product from a thick fibrous matrix (wooden blocks) lasts several weeks so targets mites as they emerge with parasitised bees. Originally formulated as thymol impregnated into ‘Homasote fiberboard’ made from recycled newspaper Randy Oliver now employs absorbent soundboardxviii that seems similar to our canite pinboard made from pulverised sugar cane waste. He employs 1” x 4” x ½” (2.5 x 10 x 1.25 cm3) blocks using a solution of thymol dissolved in denatured alcohol (methylated spirits) at a ratio of 1 g thymol to 1 mL alcohol. The blocks are then left to dry. He has also used isopropanol but it is more expensive and more is needed as thymol is less soluble in that alcohol.

Four blocks, each containing 10 grams of thymol, are placed above the brood nest inside a riser rim (Figure 1). Worker bees in contact with the blocks supply a steady stream of thymol and produce a near 100% mite kill. A pleasing outcome of his 21 day trial was that brood rearing went on uninterrupted, sometimes relocated to an upper brood nest: historically Americans have operated double brood chambers.

The simplest way to prepare the absorbent blocks is to stand them end on in extra large glass jars (the type sold in delis with anti pasta) adding a measured volume of the mixture and popping the lid on allowing the mixture to infuse. Once fully absorbed they can be laid out ‘to dry’. Thymol has a relatively low vapour pressure but, once ‘dried’, they can be stored in an airtight container or large ziplock bags.

Figure 1 Thymol infused block mite treatment.

Image Randy Oliver with permission

Note that I am currently experimenting with locally available fibre materials to ascertain which are the best to make up these ‘slow release’ thymol blocks. On the list for simple absorption trials are fibro-cement sheeting (a mixture of cellulose fibre and cement), medium density fibre board (MDF) (a cellulose and wax-resin composite) and canite sound board (compressed cellulose sugar cane fibre). Using the Oliver formula to make up 40 blocks (enough for 10 hives) will require 400 g of thymol and 400 mL of methylated spirits (metho). Canite is commonly sold in 2400×1200 mm panels, typically 10–13 mm thick, with a density of 0.35 g/cm3 so pending performance is a lightweight option.

Natural products revisited

A number of candidate natural products have been employed to bowl over mites despite the chequered record of their actually working.

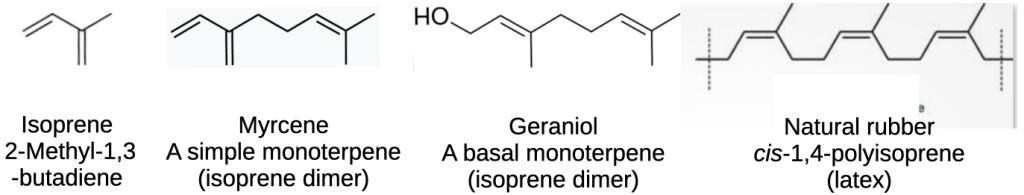

What exactly are these natural products? In a lesson from organic chemistry 101 we learn that the majority that kill mites in a petri dish are terpenes based on a simple five-carbon building block, isoprene (Figure 2). From isoprene is built the most common biosynthetic intermediate, geraniol, the main constituent of geranium and pelargonium oils. Together they are the common starting units for a host for other fragrant oils: roses, citrus, lemongrass, mint and eucalypts… but there is another isoprene base product, with which you are of course familiar. It is a linear polymer of isoprene, latex or rubber.

Figure 2 Isoprene in nature as a basic building block. Simple polymers are myrcene (verbena, wild thyme); geraniol (geranium, pelargonium) and natural rubber (unvulcanised latex rubber).

I have vivid memories of motoring past endless oil palm (Elaeis guineensis) and rubber tree (Hevea brasiliensis) plantations lining a central Sumatran highway fifty years ago. We happened upon a foul smelling rubber factory, nothing unusual you would agree. However what was surprising was its front gate emblazoned billboard:

MORNING LATEX

EVENING TYRE

How could one forget those bumps in life’s journey that are not softened by isoprene (or latex)?

Since, and despite Oliver’s skepticism about their usefulness, there are many anecdotal reports of natural oils working well. I have tabulated a few of the physical properties of the better known and more widely used oils (Table 1). In practice most might best be applied as pastes or gels that might be placed on an impervious medium (such as squares of corflute) or easily removable greaseproof paper, or absorbed into porous fibre blocks.

Mite trapping revisited

One of the advantages of getting bees to build slabs of drone comb is that this facilitates their ready removal – with mites – and is a means of relying less on chemical treatment. To boot this ‘remove many mites at once’ caper is a far more practical than searching the brood nest to decap isolated patches of drone brood.

Given any chance to construct free form-comb in colonies managed to constrain drone numbers bees will build near pure drone comb. We recognise this in drone comb construction between supers – below bottom bars – and in the broodnest of hives with a missing frame.

| Natural miticide | Sources | Melting point (0C) | Boiling point (0C) | Solubility in water (g/L), 20 0C) |

| Organic acid | 2 | |||

| oxalic acid | 189.5 | dec | 9.6 (24 EtOH, 15 0C | |

| formic acid | 8.4 | 100.8 | misc (misc EtOH) | |

| lactic acid | 18 | 122 | misc | |

| Natural product | ||||

| carvacrol | Oregano/Savory/Ethiopian thyme | 1 | 237.7 | insol (sol EtOH) |

| carvone | Caraway/Spearmint | 25.2 | 231 | insol (sol EtOH) |

| cineol (eucalyptol) | Eucalypts | 2.9 | 176-177 | insol (sol EtOH) |

| cinnamaldehyde | Cinnamon | -7.5 | 248 | sl sol (misc EtOH) |

| α citral (geranial) and βcitral (neral) | Litsea; ginger; Lemon myrtle; Lemon tea tree; African basil; lime | -10 | 226-228 | Sl sol (sol EtOH) |

| citronellal | Lemon grass | 147 | 201-207 | sl soluble (sol EtOH) |

| eugenol | Clove | -7.5 | 254 | 2.5 (misc EtOH) |

| β-hop acids | Hops | 82-97 | sl soluble | |

| menthol | Peppermint | 36-38 | 214.6 | 0.45 (sol EtOH) |

| methyl salicylate | Oil of wintergreen | -8.6 | 222 | 0.64 (sol EtOH) subl 76 0C |

| thymol | Thyme | 49-51 | 232 | 0.9 (misc EtOH) |

Table 1 Physical properties of indicative natural miticides.

In the Oliver mite trapping frame setup, bees draw out worker comb on foundation in the top section of divided standard full depth and construct pure free-form drone comb below the dividing bar (Figure 3). Such combs need to be built with a nuanced understanding of drone comb construction and drone production. In the normal circumstance a mature colony will fill the top section with stores built on worker comb foundation and build free-form wall-to-wall drone comb below the bar. This ‘stores above’, ‘brood below’ is replicated in nature but in a practical sense funnels many mites onto a single comb.

Figure 3 Oliver drone comb. Note rim of wax applied below dividing bar as a starter for free-form drone comb construction.

Since bees build comb dictated by their immediate needs, I have not been surprised to discover that in the early season phase of colony expansion bees raise some worker brood in the top section or build drone comb first in the free-form comb section and sometimes leave worker foundation undrawn. As the season progresses well colonies with ample drones will fill out the upper section with stores and start to draw out mixed free-from drone and worker comb and will use this lower section to store honey and pollen at the comb margins (Figure 4).

Figure 4 Advance in drone comb use from early-to-mid spring to mid-summer:

Mid spring (left)

(a) pure drone comb developed below horizontal division:

(b) less common pattern of mixed drone comb (centre) and peripheral production of worker comb below horizontal division; and

(c) more common pattern of drone comb development below brood shallow or ideal frame bottom bar in deep frame b chamber.

Mid summer (right)

(d) colony still raising drones but storing honey as brood ecloses;

(e) colony raising a few drones, storing honey but also building worker comb and raising workers; and

(f) colony abandoning drone raising and storing honey and, in this instance mainly pollen.

Note: The season has been poor and late: many honey super combs with foundation have remained undrawn.

The take home message is that late season drone comb production and raising of drones is slow and irregular (Figure 5). So for the purpose of building of drone mite trapping comb – and for subsequent use of these frames to trap mites – such frames should be started very early in the season.

One unintended consequence of operating hives with one (and occasionally two) such frames and leaving them in the brood nest has been that colonies have ended up with very large populations of drones. When the mites arrive shortly, leaving drone comb unattended would lead to explosive numbers of mites. My next task, therefore, will be to select the best drawn combs and store them for early mite trapping next spring.

Drone slabs (with mites) are removed on a strict three week cycle (well in advance of drone emergence). Drone comb is then either cut out and donated to the chook pen, frozen for 24-48 h or fumigated.

Note well: I use phosphine routinely to protect stored combs but do not recommend its use, that is unless you are very familiar with its safe handling. The generating aluminium phosphide tablets come in an airtight container and must be handled in the open, with gloves and treated gear (in a sealed tub) must be stored in a well ventilated area never – for several weeks after treatment – in a confined space. It works well, degrades completely and leaves only a grey aluminium hydroxide powder that can be safely disposed of in the garden.

The patterns of even later comb development and use are, however, very variable and reflect more the condition of the colony once the main drone raising season is over (Figure 5).

Figure 5 Variable colony divided comb use at the end of the drone raising season:

(a) most comb employed to raise workers with mixed free-form drone comb raising few drones; and

(b) top section employed for honey storage and drone comb being drawn very slowly and raising few drones.

Randy now proposes that the lower drone comb zone be divided into three discrete sections (with vertical dividers) to facilitate programmed weekly sealed drone brood removal. Good In principle I thought. I see this as generating more work than needed and I will instead use additional mite trapping combs if needed.

Where to with mites

In order to continue to keep bees, pollinate our berry patches and vegetables and to keep the kitchen larder well stocked we will need to keep an eye out for more ravaging mites and yet more pests. I read recentlyxix of a new species of nosema, Nosema neumanni, plaguing bees in Uganda and of course there are Asian hornets (Vespa mandarinia and Vespa velutina) right on our doorstep.

Some of the details of mite treatments will require ironing out. Oliver is yet to fully document his quick-fire formic acid treatment and we live in hope to have approved and setup details for slow release acid and thymol treatments. It will be equally important to advance the own use exemption for most treatments if only to sanctioned access to low cost natural products and to pay close attention to their formulation and safe use.

Similarly we might not lose sight of old foes, AFB, EFB, SHB and wax moth. The impact of some, such as small hive beetle and American Foulbrood, have been exacerbated by the recent sudden invasion of Varroa mitesxx. And, of course give queen rearing to breed for mite tolerance more than a casual nod.

On the small hive beetle score, we are already learning a new lesson. In combination with Varroa mites, colonies are falling prey to SHB with slime-outs common in the Sydney area. Vigilant keepers are finding they can control mites but since there is no SHB treatment, no amount of trapping is working.

Readings

iOliver, R. (2009). The Learning Curve: Part 4–The Synthetic Miticides. https://scientificbeekeeping.com/the-learning-curve-part-4-the-synthetic-miticides/

iiGrey, T. (1750). Elegy Written in a country churchyard. https://www.poetryfoundation.org/poems/44299/elegy-written-in-a-country-churchyard

iiiWade, A. (2024). Bee Buzz Box November 2024, Smite the Mite Part II – The Organic Mite Exterminators. https://actbeekeepers.asn.au/bee-buzz-box-november-2024-smite-the-mite-part-ii-organic-mite-exterminators/

ivRandy Oliver (2025). (personal communication) January 2025.

vOliver, R. (2023). Oxalic acid treatment table. Scientific Beekeeping. https://scientificbeekeeping.com/oxalic-acid-treatment-table/

viWade, A (2024). loc. cit.

viiMaggi, M., Tourn, E., Negri, P., Szawarski, N., Marconi, A., Gallez, L., Medici, S., Ruffinengo, S., Brasesco, C., De Feudis, L. and Quintana, S., (2016). A new formulation of oxalic acid for Varroa destructor control applied in Apis mellifera colonies in the presence of brood. Apidologie, 47:596-605. https://link.springer.com/content/pdf/10.1007/s13592-015-0405-7.pdf

https://hal.science/hal-01532332v1

viiiKanelis, D., Tananaki, C., Liolios, V., and Rodopoulou, M. (2023). Evaluation of oxalic acid with glycerin efficacy against Varroa destructor (Varroidae): A four year assay. Journal of Apicultural Research 63(5):847-855. https://doi.org/10.1080/00218839.2023.2169368

ixOliver, R. (2021). Mite control while honey is on the hive. Part 3. American Bee Journal 161(1):77-83. https://americanbeejournal.mydigitalpublication.com/january-2021-vol-161-no-1/77

https://scientificbeekeeping.com/mite-control-while-honey-is-on-the-hive-part-3/

xAmrine Jr, J.W. and Noel, R. (2006). Formic acid fumigator for controlling varroa mites in honey bee hives. International Journal of Acarology 32(2):115-124. https://www.wellesu.com/10.1080/01647950608684452 https://www.researchgate.net/publication/228453555_Formic_acid_fumigator_for_controlling_varroa_mites_in_honey_bee_hives

xiRandy Oliver (2024). (personal communication) December 2024.

xiiOliver, R. (March 2024). Experimenting with formic acid. Scientific Beekeeping.https://scientificbeekeeping.com/experimenting-with-formic-acid/

Oliver, R. (2024). American Bee Journal 163(3):

xiiiHoppe, H., Ritter, W. and Stephen, E.W.C. (1989). The control of parasitic bee mites: Varroa jacobsoni, Acarapis woodi and Tropilaelaps clareae with formic acid. American Bee Journal 129(11):739-742.

xivMenzies, C., Olmstead, S., McCallum, R. and Cutler, C. (2019). The efficacy of Formic Pro™ and 65% liquid formic acid against varroa mite (Varroa destructor) in honey bee (Apis mellifera) colonies in autumn in Nova Scotia, Canada. Journal of the Acadian Entomological Society 15:40-45. https://acadianes.org/journal/papers/menzies_19-5.pdf

xvOntario Ministry of Agriculture, Food and Rural Affairs (2017). Treatment recommendations for the control of mites and honey bee diseases. https://www.ontariobee.com/sites/ontariobee.com/files/Treatment%20Recommendations%202017-11-02.pdf

xviKochansky, J. and Shimanuki, H. (1999). Development of a gel formulation of formic acid for control of parasitic mites of honey bees. Journal of Agricultural and Food Chemistry 47(9):3850-3853. https://www.wellesu.com/10.1021/jf9901439

xviiOliver, R. (2022). Thymol: A new application method? Part 1 Scientific Beekeeping. https://scientificbeekeeping.com/thymol-a-new-application-method-part-1/

Oliver, R. (2022). Thymol: A new application method? Part 2. Scientific Beekeeping . https://scientificbeekeeping.com/thymol-a-new-application-method-part-2/

xviiiOliver, R. (2024). Extended release thymol blocks: Scientific Beekeeping https://scientificbeekeeping.com/extended-release-thymol-blocks/

Oliver, R. (2025). Extended release thymol blocks TBA

xixChemurot, M., de Smet, L., Brunain, M., de Rycke, R. and de Graaf, D.C. (20170. Nosema neumanni n. sp.(Microsporidia, Nosematidae), a new microsporidian parasite of honeybees, Apis mellifera in Uganda. European Journal of Protistology 61:13-19. https://www.sciencedirect.com/science/article/pii/S0932473917301001

xxAllerton, M. (February-March 2025). Biosecurity Buzz. The Amateur Beekeeper 3-5. https://www.beekeepers.asn.au/news/2025/2/1/the-amateur-beekeeper-february-march-2025